THE CTT MOISTURE CONTROL SYSTEM IS TRUE ANTI-CONDENSATION

CTT Systems is the sole provider of an active Moisture Control System (MCS). The CTT Anti-Condensation system is the only measure that actually tackles the root-cause of condensation. With active and preventive control, the aircraft will not accumulate condensate water and therefore save fuel and avoid excess greenhouse gas (GHG) emissions.

By selecting our anti-condensation moisture control system, airlines on every flight can operate with less weight and lower energy needs with less pollutant emissions.

Additional costs savings include lower repair costs of moisture related damages in electrical components and equipment, repair/replace of blankets and reduced down-time due to electrical failures.

200kg in weight reduction…

…saves 0.4% block fuel burn and…

…reduces 65mt of CO₂ emissions per year

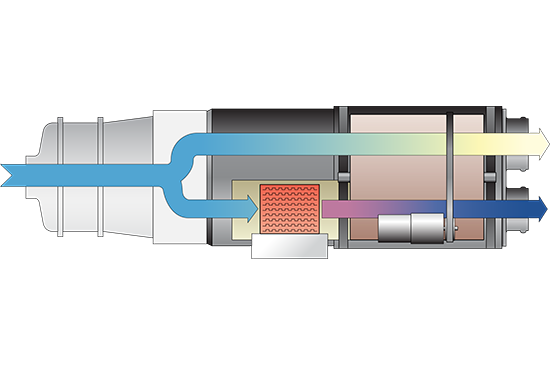

The CTT anti-condensation protection system removes trapped water in blankets, keeps the crown area dry and prevents unwanted excess weight from water accumulation. The system continue to dry the fuselage on ground-stop.

Lowers fuel burn with 0.4%-0.6% and CO₂ emissions with some 65-95mt per aircraft per year from excess weight reduction of 200 – 300kg of accumulated water in Boeing 737-800/A320 aircraft (fuel savings of 25,000 – 38,000 liters per year);

Higher operational reliability from significantly lowered moisture related faults in electrical equipment (Out-Of-Service time and repair costs);

Lower rate of insulation blanket replacement.

NON-CONDENSATION FLIGHTS ARE ALWAYS LIGHTER

The CTT Anti-Condensation system is the only measure that tackles the root-cause of fuselage condensation; resulting in less fuel burn, reduced CO₂ emissions and lowered electrical failures. Several airlines have in dedicated trials already after 2 – 3 months of moisture protected operations recorded a weight loss of 200 – 300 kg in narrowbodies.

NON-CONDENSAtioN FLIGHTS REDUCES FUEL BURN / CO2

Lowered excess aircraft weight of 200 kg, reduces block fuel consumption by around 0.4%, resulting in fuel savings of approx. 25,000 liters per year per aircraft, cutting CO₂ emissions by more than 65mt.

SIGNIFICANT REDUCTION IN ELECTRICAL FAILURES

Another airline proven benefit is a documented 40% reduction of unscheduled electrical component changes per 1,000 flight hours. Non-condensing airplanes always face less moisture issues in electrical systems.

LESS FREQUENT REPLACE / REPAIR OF BLANKETS

Moisture in blankets reduces functionality and shortens life time. More frequent repair or replace of blankets is of course a cost but also contradictory to sustainability objectives.

Moisture in aircraft blankets and structures also increases risk to spread mold in the cabin.